Cut operational costs effectively with

FactoryWiz Machine Monitoring & DNC

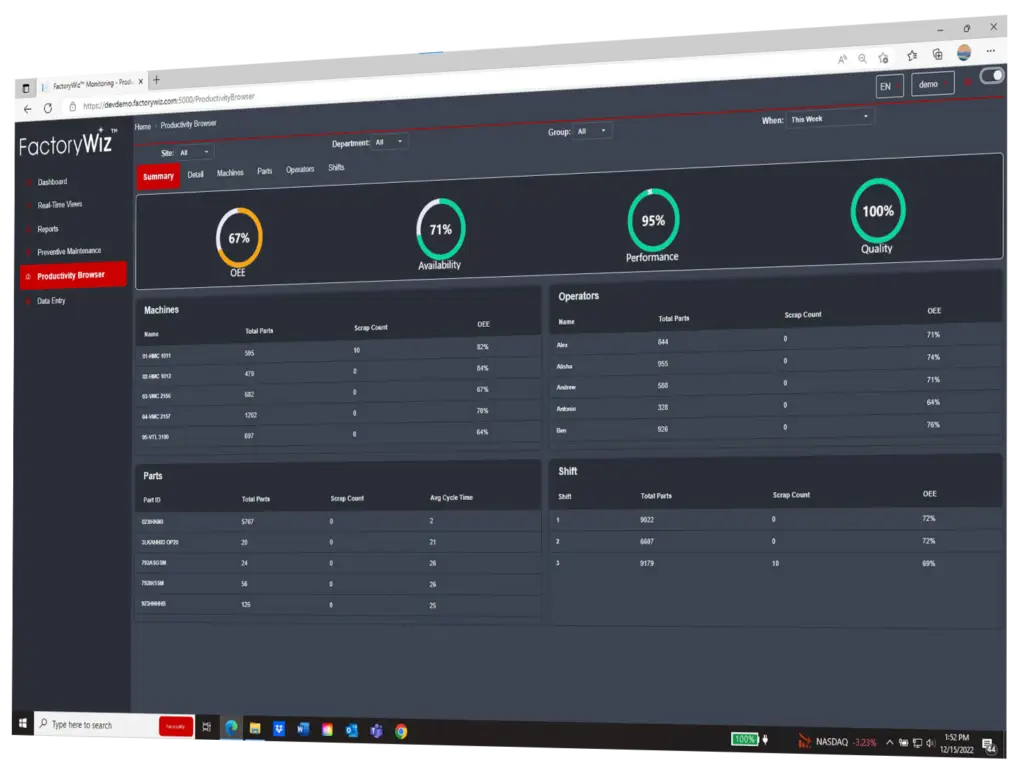

Visualize critical machine data in real-time via interactive dashboards, charts, graphs, e-mails and text messages from any web enabled device.

Receive automated daily, weekly, monthly oee reports. Compare based on machine, department, shift, or part produced.

Receive alert notifications on any web enabled device. Alarms, part count, machine conditions and maintenance schedules.

Identify operation bottlenecks and production improvement opportunities with our smart monitoring system.

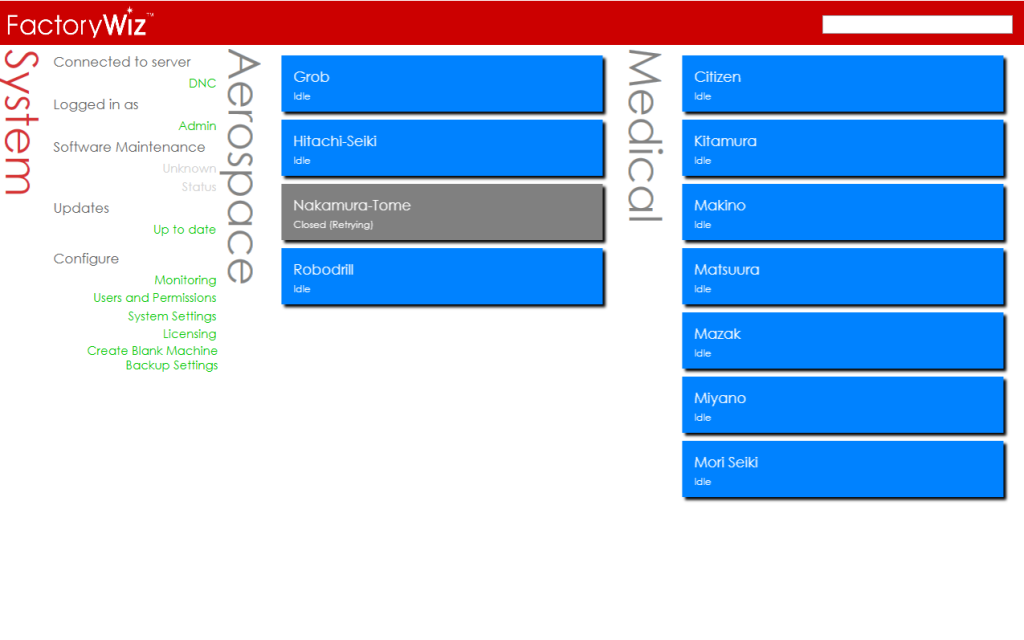

FactoryWiz has one of the largest machine connection libraries in the industry. While modern equipment utilize industry standard Ethernet connections such as Fanuc Focus, MT Connect, OPC-UA, UMATI, etc. FactoryWiz also excels at connecting and collecting data from older equipment never equipped with native Ethernet capabilities.

Compatible with:

CNC Machines – Additive Machines – Robots – Fabrication Equip – Furnaces – Compressors – Process PLC’s – Other shop assets…

“We needed a way to figure out how our machines were cutting, and we needed raw data to help us understand what was happening on the shop floor”

-Marzel Neckien

Owner W Machine Works Inc.

In business since 1892, Freeman has evolved and grown tremendously over that time, and part of that evolution was the investment in Machine Monitoring software.

FactoryWiz DNC is the newest, most modern DNC software on the market, designed from the ground up to be simple, streamlined on Windows 7, 8 and 10 devices.

At W Machine Works, Owner Marzel Neckien discusses why they chose FactoryWiz to monitor machine tools and act as a platform to facilitate shop floor communication.

"Machine monitoring helps work remotely, avoid close contact on the shop floor and prevent underbilling for lights-out machining." An article by Matt Danford.