Machine monitoring

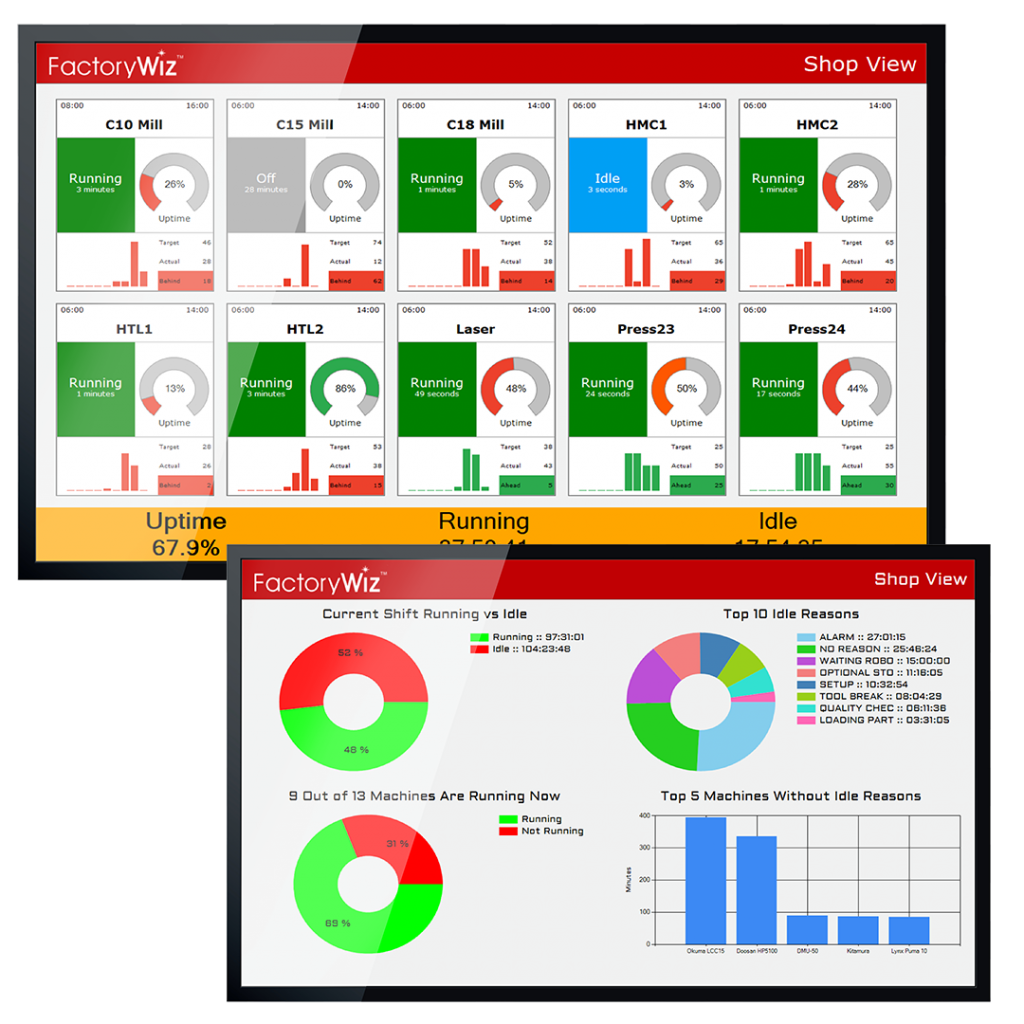

It’s what many call the “Smart Factory”. In short, it’s an Ethernet connected factory using software systems like FactoryWiz Monitoring. Collect activity status on assets such as CNC machines, robots or assembly lines and present real-time non-biased information. Thus, allowing management to take immediate corrective action as well as make future informed decisions based on historical facts.

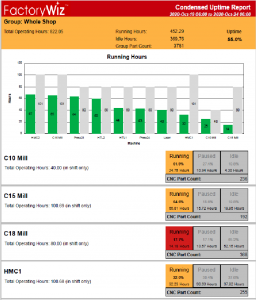

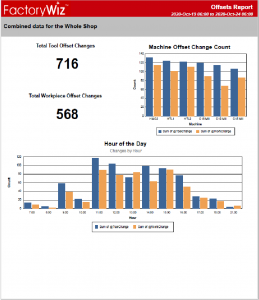

FactoryWiz Machine Monitoring is a complete turn-key intranet monitoring solution. All collected activity status is automatically timed stamped by the attached machine/asset. Also, gathered records can be displayed in real-time on interactive dashboards on any web enabled device. Additionally, historical reports can be executed on demand or automatically scheduled for e-mail delivery.